1. Introduction and the Principle of Color Changing

Memory Type Thermochromic Material is a color-change-reversible material with memory effect. It changes color when temperature is above 55℃ and recovers color when temperature drops below 0℃.

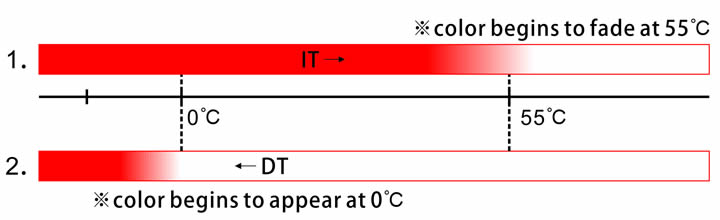

1. As the picture shown below: The material is colored at 25℃. The color starts to fade at 55℃ and disappears at the range 58~62℃ (depends on color). The color will not reappear until temperature drops below 0℃.

(IT: Increasing Temperature; DT: Decreasing Temperature)

2. As the picture shown above: The material is colorless at 25℃. The color begins to show at 0℃ and 100% appears at the range -10~-15℃ (depends on color). The color will not disappear until temperature reaches 55℃.

2. Features

1.Color of the material can be set—in the range of 0℃ to 55℃, the material can be set to colored or colorless.

2.Can be used as an irreversible material. For example, erasable ink.

A. Applications:

Ink, paint, printing, textile…etc.

B. Color:

Red, rose red, magenta, orange, yellow, charm green, green, blue, turquoise blue, dark blue, violet, black and brown.

3. Form:

Slurry. Low formaldehyde modified slurry for ink. Low formaldehyde ink.

A. Memory Type Thermochromic Slurry (TM-SL W50-0):

- A microcapsule aqueous dispersion with good dispersal in water

- Solid Content 35% (±5%)

- Particle Size D50 0.9-1.3μm D97 2.2-2.8μm

- Recommended Concentrations For aqueous based ink/paint 5%~60% w/w (25%)

B. Memory Type Thermochromic Low Formaldehyde Modified Slurry For Ink (TM-MSL W50-0):

- A water-based microcapsule dispersion which can be made into roller ball pen ink

- Solid Content 35 % (±5%)

- Particle Size D50 0.9-1.3μm D97 2.2-2.8μm

- Recommended Concentrations for ink 40%~45% w/w

C. Memory Type Thermochromic Low Formaldehyde Ink (TM-INK W50-0):

- Applicable in water-based system, such as gel pen ink, color pen…etc

- Slurry Content 35~40%

4. Others:

Certifications: RoHS & EN-71passed