A. Introduction

Photochromic materials absorb the energy of sunlight/UV rays to produce changes in their molecular structure. The change in the absorption wavelength causes color changes. As the energy of sunlight/UV rays is lost, the original molecular structure is restored and return to the original color. This is a reversible color change.

B. Discoloration Principle

|

Without UV rays: Colorless |

Under UV rays: Colored |

|

|

|

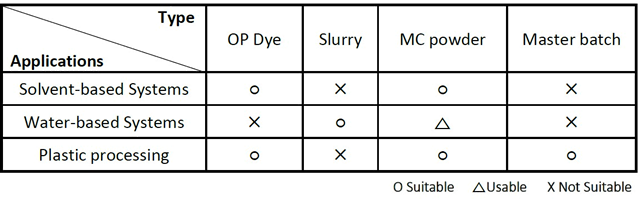

C. Product Type and Applicable Table

1. OP Dye: Suitable for solvent-based systems and plastic processing.

2. Slurry: Suitable for water-based systems.

3. MC powder: Suitable for solvent-based systems and plastic processing.

4. Master batch: Suitable for plastic processing.

D. Product introduction and instructions

1. OP Dye

1.1 Colors (For reference only)

|

|

|

|

|

#12 Purple

|

#13 Sky Blue

|

#14 Blue

|

#16 Yellow

|

|

|

|

|

|

#17 Peach Orange

|

#18 Orange

|

#19 Magenta

|

#22 Grey

|

|

|

|

|

|

#33 Grenadine

|

#34 Carmine

|

#62 Dark Jungle Green

|

#84 Amethyst

|

1.2 Description

![]() OP dye itself does not change color when irradiated and needs to be dissolved in a medium such as solvents, resins, and plastics, to be sensitive to UV rays to change in color. It shows different color edge in different polarities.

OP dye itself does not change color when irradiated and needs to be dissolved in a medium such as solvents, resins, and plastics, to be sensitive to UV rays to change in color. It shows different color edge in different polarities.

1.3 Properties

![]() OP dyes are organic dyes, which can achieve complete light transmission. It can be used in plastic processing, solvent-based inks and coatings. Different colors of OP dyes have different degrees of color development and decolorization speed.

OP dyes are organic dyes, which can achieve complete light transmission. It can be used in plastic processing, solvent-based inks and coatings. Different colors of OP dyes have different degrees of color development and decolorization speed.

1.4 Usage (e.g. 20μm film formation, 0.2cm plastic molding)

![]() For solvent based ink/paint 0.02%-0.3% w/w (0.5%)

For solvent based ink/paint 0.02%-0.3% w/w (0.5%)

![]() For plastic injection/extrusion 0.01%-0.3% w/w (0.01%)

For plastic injection/extrusion 0.01%-0.3% w/w (0.01%)

1.5 Precautions

![]() Processing temperature: When applied to plastic injection and extrusion, processing temperature should be lower than 200℃. Heat stabilizer can be added.

Processing temperature: When applied to plastic injection and extrusion, processing temperature should be lower than 200℃. Heat stabilizer can be added.

![]() Light fatigue: UV light overexposure, acid, free radicals and humidity will cause the light fatigue of the photochromic material. It is recommended to add UV absorbers and antioxidants to increase light fastness, but too much UV absorber may block the absorption of UV rays, resulting in poor discoloration effect, or even failure to discolor.

Light fatigue: UV light overexposure, acid, free radicals and humidity will cause the light fatigue of the photochromic material. It is recommended to add UV absorbers and antioxidants to increase light fastness, but too much UV absorber may block the absorption of UV rays, resulting in poor discoloration effect, or even failure to discolor.

![]() Solubility: Different colors of OP dyes have different solubility in formulations. Our standard formulations can be used for inks and coatings. For the solubility of OP dyes in different solvents, please contact us.

Solubility: Different colors of OP dyes have different solubility in formulations. Our standard formulations can be used for inks and coatings. For the solubility of OP dyes in different solvents, please contact us.

2. Photochromic Slurry

2.1 Colors (For reference only)

|

|

|

|

|

#31 New Magenta

|

#32 Red

|

#33 Grenadine

|

#34 Carmine

|

|

|

|

|

|

#41 New Orange

|

#51 New Yellow

|

#61 Green

|

#62 Dark Jungle Green

|

|

|

|

|

|

#71 New Blue

|

#72 Turkish

|

#73 Canal Blue

|

#81 New Purple

|

|

|

|

|

|

#82 Deep Purple Blue

|

#83 Vivid Reddish Purple

|

#84 Amethyst

|

#91 Dark Charcoal Grey

|

2.2 Description

![]() Photochromic slurry is a microencapsulated aqueous dispersion with good dispersal in water, suitable for water based paint.

Photochromic slurry is a microencapsulated aqueous dispersion with good dispersal in water, suitable for water based paint.

![]() Particle size: less than 5μm

Particle size: less than 5μm

![]() Solid content: 40±5%, different content for different colors.

Solid content: 40±5%, different content for different colors.

2.3 Properties

![]() Protected by microcapsules, photochromic slurry can change color steadily. The water emulsion is a pigment type. Different models will produce varying degrees of masking effects.

Protected by microcapsules, photochromic slurry can change color steadily. The water emulsion is a pigment type. Different models will produce varying degrees of masking effects.

2.4 Usage(e.g. 20μm film formation)

![]() For aqueous based ink/paint 5%-60% w/w (25%)

For aqueous based ink/paint 5%-60% w/w (25%)

2.5 Precautions

![]() Slurry may gather together during storage. Heat the slurry to 45℃ in a double boiler to disperse.

Slurry may gather together during storage. Heat the slurry to 45℃ in a double boiler to disperse.

![]() Avoid any high polarity solvents since the microcapsules may be permeated and the contents may be affected.

Avoid any high polarity solvents since the microcapsules may be permeated and the contents may be affected.

3. Photochromic Microcapsulated Powder

3.1 Colors (For reference only)

|

|

|

|

|

#31 New Magenta

|

#32 Red

|

#33 Grenadine

|

#34 Carmine

|

|

|

|

|

|

#41 New Orange

|

#42 Melon Orange

|

#51 New Yellow

|

#61 Green

|

|

|

|

|

|

#62 Dark Jungle Green

|

#71 New Blue

|

#72 Turkish Blue

|

#73 Canal Blue

|

|

|

|

|

|

#81 New Purple

|

#82 Deep Purple Blue

|

#83 Vivid Reddish Purple

|

#84 Amethyst

|

|

|

|||

|

#91 Dark Charcoal Grey

|

3.2 Description

![]() Photochromic microencapsulated powder contains 2-5 % photochromic dye. Suitable for solvent and aqueous based ink/paint and plastic injection and extrusion.

Photochromic microencapsulated powder contains 2-5 % photochromic dye. Suitable for solvent and aqueous based ink/paint and plastic injection and extrusion.

![]() Particle size: less than 10μm

Particle size: less than 10μm

![]() Moisture content: less than 3%

Moisture content: less than 3%

3.3 Properties

![]() Photochromic microencapsulated powder is a pigment with bright color, high temperature resistance and solvent resistance. It can be used in plastic processing, oil-based inks and coatings.

Photochromic microencapsulated powder is a pigment with bright color, high temperature resistance and solvent resistance. It can be used in plastic processing, oil-based inks and coatings.

3.4 Usage(e.g. 20μm film formation, 0.2cm plastic molding)

![]() For solvent/aqueous based ink/paint 3%-30% w/w (25%)

For solvent/aqueous based ink/paint 3%-30% w/w (25%)

![]() For plastic injection/extrusion 0.2%-1% w/w (0.05%)

For plastic injection/extrusion 0.2%-1% w/w (0.05%)

3.5 Precautions

![]() Processing temperature: When applied to plastic injection and extrusion, processing temperature should be lower than 200℃. Heat stabilizer can be added.

Processing temperature: When applied to plastic injection and extrusion, processing temperature should be lower than 200℃. Heat stabilizer can be added.

4. Photochromic Masterbatch

4.1 Description

![]() Our standard photosensitive masterbatch is made by mixing 1% photochromic dye and 99% plastic material, UV stabilizer and antioxidant.

Our standard photosensitive masterbatch is made by mixing 1% photochromic dye and 99% plastic material, UV stabilizer and antioxidant.

4.2 Properties

![]() Dispersed and used easily, can be directly applied to plastic injection/extrusion.

Dispersed and used easily, can be directly applied to plastic injection/extrusion.

4.3 Usage(e.g. 0.2cm plastic molding)

![]() For plastic injection/extrusion 1%-5% w/w(1%)

For plastic injection/extrusion 1%-5% w/w(1%)

4.4 Precautions

![]() Standard material: PE.

Standard material: PE.

![]() Other available material: PP. TPU. TPR. EVA.

Other available material: PP. TPU. TPR. EVA.

![]() Photochromic masterbatch is made with special formulations. Its color changing effect is different from the effects of photochromic powder and dye

Photochromic masterbatch is made with special formulations. Its color changing effect is different from the effects of photochromic powder and dye

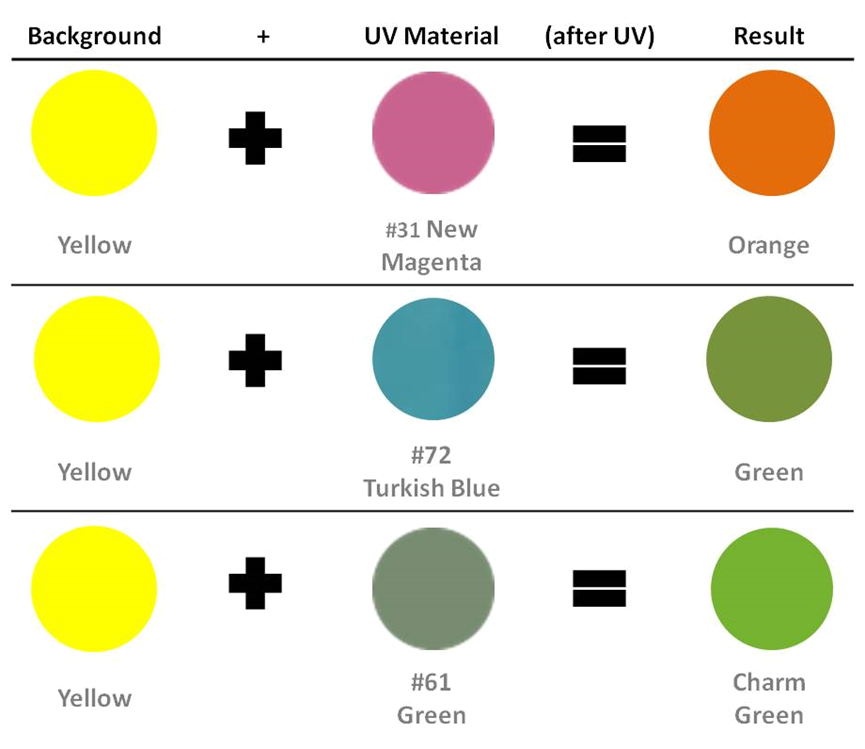

E. Miscellaneous

1. Colored to colored (For reference only)

2. Besides photochromic dyes, all the other photochromic materials are in pigment forms, which exists various levels of coverage effects.

3. The light fastness of the photochromic products should be thoroughly tested prior to approval for production.

4. Storage: Store in a dry and cool place and keep away from sunlight. Shelf life: 2 years.

5. Photochromic series have passed EN 71 and RoHS tests. Can be used in food packaging and toy manufacturing.

1、Theory

By taking the advantage of bamboo charcoal’s porosity and the ability to release far infrared radiation, the nano-size bamboo charcoal powders, which went under a high temperature sintering and be added into plastic particles, can be used as an adsorption, filtration and thermal storage material. Inorganic silver irons were added into pores to provide the merit of antibacterial.

2、Description

1.Native product “Moso Bamboo” as material

, and using the technique from “Council of Agricultural in Taiwan” that doing the carbonization at high temperature inside the soil kiln to produce bamboo charcoal. Utilizing the key technique of nano which is researched by Taiwan Textile Research Institute, bamboo charcoal will be grinded into powder and add in inorganic silver irons to make PET master batch. This kind of bamboo charcoal yarn which underwent nano-grade grinding process has not only dense structure, more pores, but also contains abundant of minerals, being able to release far infrared radiation, possesses functions of heat storage and deodorant. Test report shows that the far infrared radiation heating value of bamboo charcoal can be 8℃ or more, indicates that it is a excellent heat-accumulating textile.

In addition, the silver irons within the master batch have good antibacterial effect against E. coli, Staphylococcus and Pseudomonas aeruginosa.

Since the material is not dipped on the surface but evenly distributed in the fiber structure, it has good fastness to laundering and can be washed in any way without affecting the function. There is also good workability and dying affinity.

2.Color: Dark grey

3、Main Ingredients

Bamboo charcoal, inorganic nano silver, PET

4、Function

Strong adsorption, deodorant, alter humidity, heat storage and antibacterial effect.

5、Properites

1.Density: Bamboo charcoal 10%

2.Basic Specification

| TYPE | Copolymer |

| I.V. ([η]) | 0.50±0.02 |

| Moisture Content (wt %) | <0.5 |

| Melting Point(℃) | 246±4 |

| Molding Temp.( ℃) | 275-285 |

| Acid Value (COOH)( 10-6equ/g) | 30MAX |

6、Precautions

Keep away from sunlight. Avoid inclusions such as Cl-, NO3-, which tend to react with silver ions.