1 Introduction

Irreversible Thermochromic Ink is a water-based ink which only can change the color one time. The color is generated by the reaction of color forming agents (Leuco dye and color developer). The color forming agents do not react until a sensitizer melts and create enough vicinity between the color forming agents. We choose different melting point of the sensitizer to control which temperature to start the reaction.

2 Product Description

A. Color Convesion:

The color will change from near white to Magenta or black when Temperature reach specifc degree.

| Colored as temperatures raise |  |

|

Colorless as temperatures cool down | |

| Colored as temperatures raise |  |

|

Colorless as temperatures cool down |

B. Available Activation Temperature:

60℃、75℃、90℃、115℃。

C. Color: Black or Magenta.

Black:60℃、75℃、90℃、115℃

Magenta:60℃、75℃、90℃

3 Applications

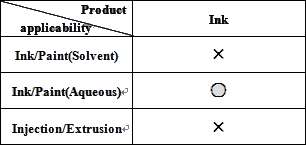

A. Available Product & Applicability

○Applicable、×Not Applicable.

B. Irreversilbe Thermochromic Ink

a. Product Description:

![]() It is water-based thermochromic ink for plastic films or absorbent paper and board substrates. When Temperature goes up to the setting point, the color will start to appear, and won’t turn back when Temperature goes down.

It is water-based thermochromic ink for plastic films or absorbent paper and board substrates. When Temperature goes up to the setting point, the color will start to appear, and won’t turn back when Temperature goes down.

Pigment Content (%):29±2

Pigment Size (µm):95%< 10 microns

Solid Content (%):about 40%

Solvent:Water

Viscosity@25ºC:1700 ~3400cps

b. Properties:

![]() It’s an ink suitable for silk screen printing.

It’s an ink suitable for silk screen printing.

c. Printing Parameters:

![]() Recommended Mesh Size:120T/310 (European/US)

Recommended Mesh Size:120T/310 (European/US)

![]() Minimum Mesh Size:150T/379

Minimum Mesh Size:150T/379

d. General Recommendtion:

![]() Avoid the ink to sit dormant on the screen as this will cause ‘drying in’ on the screen and affect print definition and quality.

Avoid the ink to sit dormant on the screen as this will cause ‘drying in’ on the screen and affect print definition and quality.

![]() If you need to over print on a surface pre printed using offset inks it is recommended that the offset inks are wax free to reduce the risk of ink reticulation.

If you need to over print on a surface pre printed using offset inks it is recommended that the offset inks are wax free to reduce the risk of ink reticulation.

4 Additional Remark

chart

-ID-DT_TMP_ENG.jpg)

Irreversible themochromic inks are inherently susceptible to damage by UV light.Were necessary a cover layer with UV absorber should be used to slow degradation caused by UV light.

They are only recommended for use in applications were there will be minimal exposure to UV light.

Were necessary a cover layer with UV absorber should be used to slow degradation caused by UV light.

5 Others

A. Storage and Expiratory date:

Keep sealed in a dark, cool place, and away from directly sunlight. Preferably store below 20ºC, but do not freeze.

Shelf Life of this ink is 6 months.

B. Certifications:

EN-71 and RoHS passed.

1. Introduction

The core contents of thermochromic microcapsule are leuco-dye, color developers and temperature controllers. By using different temperature controllers, NCC thermochromic products come in various activation temperatures.

2. Product Description

A. Color Conversion:

When the temperature is raised to a specified temperature, it goes from colored to colorless. The product returns to the original color as the temperature cools down.

| Colored as temperatures cool down |  |

|

Colorless as temperatures raise |

B. Available Activation Temperatures:

–15℃ ~ 70℃

C. Color:

15 available colors for each activation temperature. (Except 70℃, only black and dark blue available for 70℃) All colors can be mixed with each other or added other pigments.

|

|

|

|

|

Red

186C |

Rose Red

238C |

Margenta

Rubine Red C |

Brown

497C |

|

|

|

|

|

Vermilion

185C |

Orange

021C |

Yellow

387C |

Charm Green

Green C |

|

|

|

|

|

Green

335C |

Sky Blue

313C |

Turkish Blue

320C |

Blue

301U |

|

|

|

|

|

Dark Blue

294C |

Violet

2728C |

Black

Black 5C2X |

3. Applications

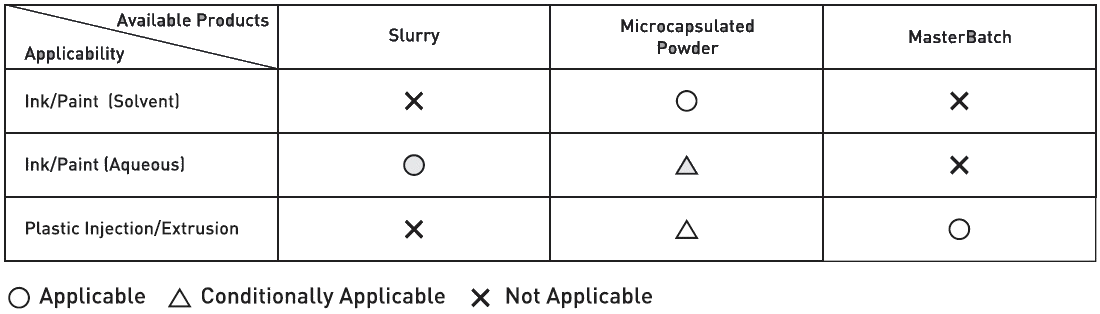

A. Available Products & Applicability

B. Thermochromic Slurry

a. Product Description

![]() Thermochromic slurry is microencapsulated aqueous dispersion with good dispersal in water, suitable for water based ink, paint. It contains 45%(±5%) of solid content. The average particle size of the slurry is 3-10µm.

Thermochromic slurry is microencapsulated aqueous dispersion with good dispersal in water, suitable for water based ink, paint. It contains 45%(±5%) of solid content. The average particle size of the slurry is 3-10µm.

b. Properties

![]() Good dispersal in water, suitable for aqueous based screen printing, paint, and ink.

Good dispersal in water, suitable for aqueous based screen printing, paint, and ink.

c. Recommended Concentrations

![]() For aqueous based ink/paint 5%~60% w/w

For aqueous based ink/paint 5%~60% w/w

(For best results, about 25% concentration is required for 20µm film thickness)

d. General Recommendations

![]() Avoid high polarity solvents, such as methanol, ethanol, acetone and methyl-ethyl-ketone, which will affect the microcapsules contents through permeation.

Avoid high polarity solvents, such as methanol, ethanol, acetone and methyl-ethyl-ketone, which will affect the microcapsules contents through permeation.

![]() Slurry may clump together during storage. Heating the slurry to 45℃ in a double boiler to disperse.

Slurry may clump together during storage. Heating the slurry to 45℃ in a double boiler to disperse.

![]() Changes of PH may cause changes of color conversion.

Changes of PH may cause changes of color conversion.

C. Thermochromic Microcapsulated Powder

a. Product Description

![]() Consist of compound formulation, containing moisture ≦ 3%. Its average particle size is 3-10µm.

Consist of compound formulation, containing moisture ≦ 3%. Its average particle size is 3-10µm.

b. Properties

![]() With good solvent resistance and dispersal, thermochromic microencapsulated powder is suitable for ink/paint and plastic injection/extrusion.

With good solvent resistance and dispersal, thermochromic microencapsulated powder is suitable for ink/paint and plastic injection/extrusion.

c. Recommended Concentrations

![]() For solvent/ aqueous based ink/paint 5%~30% w/w

For solvent/ aqueous based ink/paint 5%~30% w/w

(For best results, about 25% concentration is required for 20µm film thickness)

![]() For plastic injection/extrusion 0.1% ~5% w/w

For plastic injection/extrusion 0.1% ~5% w/w

(For best results, about 0.5% concentration is required for 0.2cm plastic thickness)

d. General Recommendations

![]() Avoid high polarity solvents, such as methanol, ethanol, acetone, and methyl ethyl ketone, which will affect the microcapsules contents through permeation.

Avoid high polarity solvents, such as methanol, ethanol, acetone, and methyl ethyl ketone, which will affect the microcapsules contents through permeation.

![]() The processing temperatures of plastic applications should not be over 230℃.

The processing temperatures of plastic applications should not be over 230℃.

D. Thermochromic Masterbatch

a. Product Description

![]() Thermochromic masterbatch contains 12%-18% of microcapsules. The percentage of microcapsules contained depends on its different color formulations.

Thermochromic masterbatch contains 12%-18% of microcapsules. The percentage of microcapsules contained depends on its different color formulations.

b. Properties

![]() Dispersed and used easily, can be directly applied to plastic injection/extrusion.

Dispersed and used easily, can be directly applied to plastic injection/extrusion.

c. Recommended Concentrations

![]() For plastic injection/extrusion 1% ~5% w/w

For plastic injection/extrusion 1% ~5% w/w

(For best results, about 0.5% concentration is required for 0.2cm plastic thickness)

d. General Recommendations

![]() Standard masterbatch is PE masterbatch.

Standard masterbatch is PE masterbatch.

![]() Add phenolic heat stabilizers only may destroy the color changing properties.

Add phenolic heat stabilizers only may destroy the color changing properties.

![]() UV stabilizer/absorbent may affect the color changing properties.

UV stabilizer/absorbent may affect the color changing properties.

4. Miscellaneous

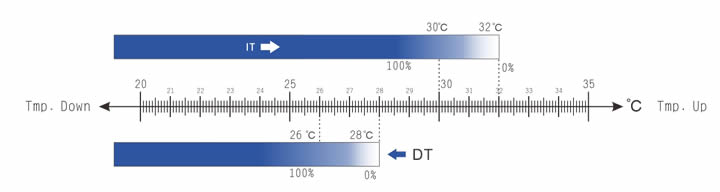

A. IT&DT chart

Chart of color change to temperatures: Exp. 31℃ Dark Blue.

![]() When temperature is going up to 30℃, red color begins fading. The color completely disappears at 32℃.

When temperature is going up to 30℃, red color begins fading. The color completely disappears at 32℃.

![]() When temperature is going down to 28℃, red color begins appearing. The color is strongest at 26℃.

When temperature is going down to 28℃, red color begins appearing. The color is strongest at 26℃.

![]() Please note each color has its specific activation temperatures. The heat conduction speed of base materials does affect the thermochromic products reactions to temperatures.

Please note each color has its specific activation temperatures. The heat conduction speed of base materials does affect the thermochromic products reactions to temperatures.

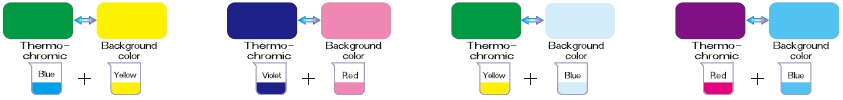

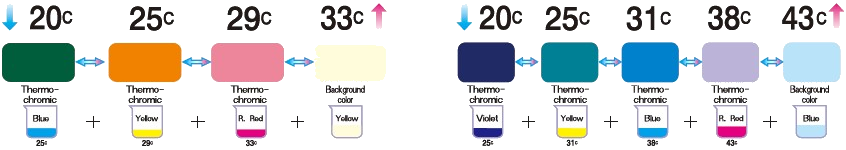

B. Multi-Phase Color Change

a. Two-phase Color Change

b. Three-phase Color Change

c. Multi-phase Color Change

5. Others

A. Storage: Keep sealed in a dark, cool place, away from direct sunlight.

B. Expiratory date: Half year for Dark Blue, Charm Green, Turkish Blue and Brown from the date of manufacture. Two years for the others.

C. Certifications: EN-71 & RoHS passed. Safe for food grade packing and toys.